Think your waterproof watch can handle anything? Beware: water remains the number one enemy of watch mechanisms, and the figures displayed (ATM, BAR, meters) only tell part of the story.

In this comprehensive guide to watch water-resistance, find out why water resistance is never an absolute guarantee, how ISO 22810 and ISO 6425 standards define actual limits, and which key components (rubber gaskets, screw-down crown, reinforced glass) transform a simple watch into a water sports ally.

From theory to practical precautions, every detail counts to protect your precious accessory from the vagaries of humidity.

A watch’s water-resistance measures its ability to withstand water pressure. It protects the internal mechanism from moisture, corrosion and damage.

Good water resistance guarantees the reliability of the movement and prolongs the life of the timepiece.

The ISO 22810 and ISO 6425 standards define water-resistance criteria for watches. The former applies to water-resistant models for everyday use, the latter to professional diving watches. ISO 6425 tests are therefore more demanding, requiring a minimum water resistance of 100 meters and evaluations in extreme conditions.

Water resistance indications in meters do not reflect the actual depth of use. A watch water-resistant to 30 meters is not suitable for this immersion. Static pressure differs from dynamic pressure. Seals degrade over time, reducing water resistance.

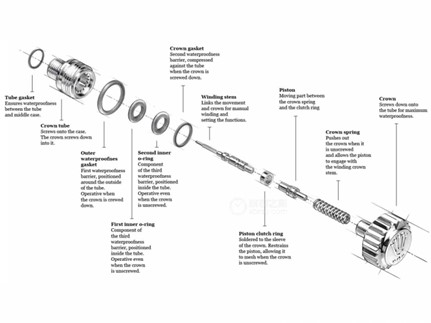

Important components for a good seal

Rubber seals form the first line of defense against water. These flexible components adapt to the irregularities of metal surfaces to create an effective seal.

Their elasticity compensates for mechanical play while resisting temperature variations and chronological wear. A modern watch incorporates several gaskets strategically positioned to protect every sensitive point.

The case components form a complete protection system to preserve the watch mechanism:

- Rubber or silicone gaskets: placed between the case, crown, pushers and back to create a watertight barrier

- Stainless steel housing: designed to withstand pressure and prevent water ingress

- Screw-down crown: reinforced clamping mechanism to block moisture at the vulnerable point

- Glass with special seals: Held in place by “I” and “L” seals to prevent fogging

Rubber gaskets ensure watertightness by adapting to the shape of the case. Lubricating grease reinforces their resistance to water.

These components work in synergy to provide optimum protection against external aggressors.

The screw-down crown is a strategic element in water resistance. It is inserted into a threaded tube on the case and locked by tightening.

This mechanical system prevents water from seeping through the access point to the winding stem. For deep dives, this mechanism comes with reinforced seals to maintain water-resistance under high pressure.

Technological innovations for greater water resistance

Modern materials improve the efficiency of traditional seals. Synthetic polymers are gradually replacing standard rubber, offering longer life and better chemical resistance. Watchmaking research is focusing on optimizing gasket profiles for more reliable sealing over time.

Professional diving watches incorporate safety systems to protect against extreme pressure. The helium valve allows helium molecules to be expelled after saturation dives. These watches undergo isostatic tests under pressure equivalent to 200 meters, exceeding the requirements of ISO 6425. Reinforced titanium or stainless steel cases protect the movement against hydromechanical shocks.

Manufacturers carry out rigorous tests to validate water-resistance before marketing. The watch is immersed in a pressurized cell, with the slightest leak detected. A final test verifies the absence of misting on the glass after temperature variations. Despite these checks, the natural wear and tear of the gaskets means that periodic maintenance is essential to maintain original performance.

Waterproofing in practice: use for different activities

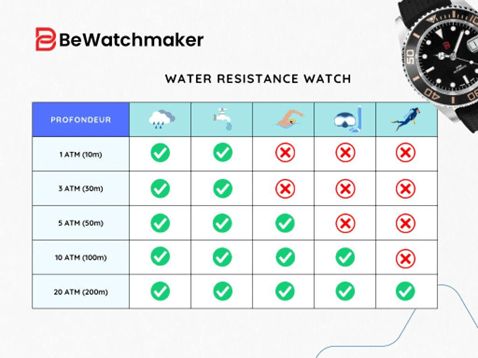

A 3 ATM watch is suitable for splashes and rain. It can withstand hand washing, but should not be immersed. Hot shower water can damage the seals. The indication of 30 meters does not correspond to the actual depth of use , but to the static pressure supported.

5 ATM watches withstand 50 meters of static pressure. They are suitable for non-diving baths, showers and hand washing. Avoid sudden temperature changes. Chlorine and salt accelerate seal degradation. Rinse with clean water after exposure to these elements.

The 10 ATM models withstand prolonged immersion. They are ideal for intensive swimming and snorkeling. The dynamic pressure of movement in water is lower than the static pressure of depth. These watches resist surface water shock, but are not suitable for scuba diving. Configure your watch for the water-resistance you need to suit your needs and activities.

Diving watches: specific characteristics and requirements

An ISO 6425-certified diver’s watch must withstand a static depth of 100 meters. It features a unidirectional bezel for precise measurement of dive time. Tests include immersion to 125% of the indicated depth.

Dive watches feature a unidirectional rotating bezel to prevent misreading. Dial hands and hour markers are coated with SuperLuminova, a phosphorescent material enabling divers to read the time in the dark depths.

Minimum water resistance is 200 meters, tested to 250 meters.

They are resistant to thermal shock and corrosion. Professional models include helium valves for bell diving.

The first diving watches appeared at Seiko in 1965. The Panerai Radiomir was created in 1936 for the Italian navy. Today, these historic models influence the design of sport-chic watches. Their robustness inspires modern diving collections.

Practical tips for keeping your watch water-resistant

Avoid extreme temperature variations. Do not handle plungers under water. Rinse with clean water after contact with salt or chlorine. Have the seal checked annually by a professional.

After swimming in the sea or a chlorinated pool, rinse with fresh water. Salt and chlorine accumulate in joints. Temperature variations cause expansion, creating micro-cracks. These chemical and thermal stresses reduce water resistance.

Have the seal checked annually, especially on 30M+ models. Professional testing detects weaknesses before they damage the mechanism. Worn seals let moisture through, causing irreversible oxidation.

Avoid extreme environments that test the limits. Accidental immersion can exceed 10 bar. Chemicals such as sunscreen attack seals. Sudden movements in water generate unexpected pressures.

Understanding a watch’s water-resistance (ATM, meters, ISO standards) and its key components (gaskets, crown) guides its use. Proactive maintenance and daily precautions prevent damage. Your watch deserves this vigilance to defy water, day after day.